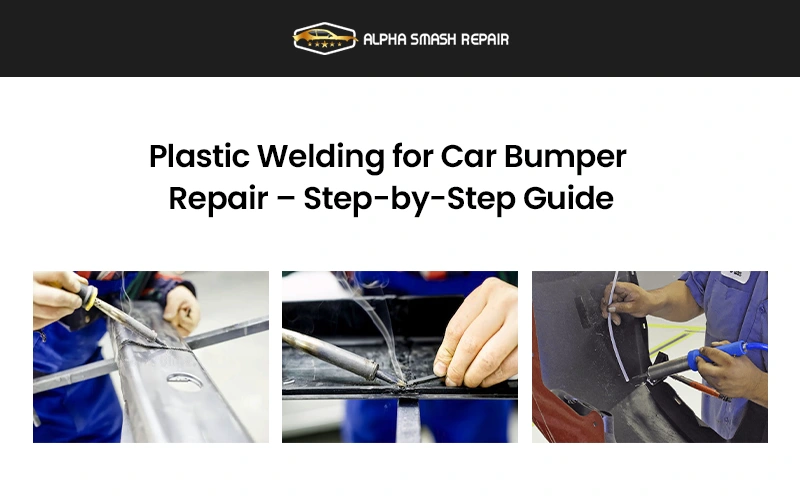

An innovative, budget-friendly, and efficient way to repair cracked or damaged bumpers at home

What is Plastic Welding?

Plastic welding is a modern technique that involves using heat to melt the plastic and bond it back into one solid piece.

Tools Needed for Plastic Welding

Plastic Welder

Primary tool to melt the plastic

Welding Rods

Used to fill in the cracks

Sandpaper

To prepare the surface for welding

Clamp

Helps hold the crack in place

Step-by-Step Process to Weld a Cracked Bumper

1Prepare the Surface

Clean the cracked area using sandpaper to remove dirt, debris, and old paint.

2Align the Crack

Use clamps to hold the cracked pieces in place, ensuring proper alignment while welding.

3Heat the Plastic

Set the plastic welder temperature between 500°F and 600°F to heat the cracked area.

4Apply the Welding Rod

Insert the rod into the melted plastic, filling the crack and bonding the pieces together.

5Smooth the Welded Area

After cooling, smooth the welded area with sandpaper until it matches the bumper level.

6Clean and Finish

Clean with a cloth and paint with matching car paint. Apply a paint finish for smooth appearance.

Common Plastic Welding Mistakes

Pros and Cons of Plastic Welding

Pros

Cost-Effective

More affordable than car bumper replacement

Fast Repair

Restore showroom quality within an hour with proper tools

Eco-Friendly

Helps reduce environmental waste

Durability

Long-lasting results that withstand daily wear and tear

Cons

Not Suitable for All Plastics

Luxury car bumpers may require specialized techniques

Time-Consuming

Takes time for beginners to complete repairs

Skills Required

Requires certain skill level for seamless results

When to Choose Welding vs Other Methods

Choose Plastic Welding When:

- Small crack or tear in the bumper

- You want durable, lasting repair

- Bumper is made of polypropylene or polyethylene

- New bumper cost is higher than welding

Consider Other Methods When:

- Damage is extensive

- Plastic bumper is difficult to weld

- You prefer adhesive or repair kits

Conclusion: Repair Smart, Save More

Plastic welding is a valuable skill for restoring the appearance and functionality of your car while saving both money and time.

Key Considerations:

By weighing every point, you can decide when to choose plastic welding or other methods for car bumper repair, ensuring your vehicle looks its best and is roadworthy again.